Brake Pads

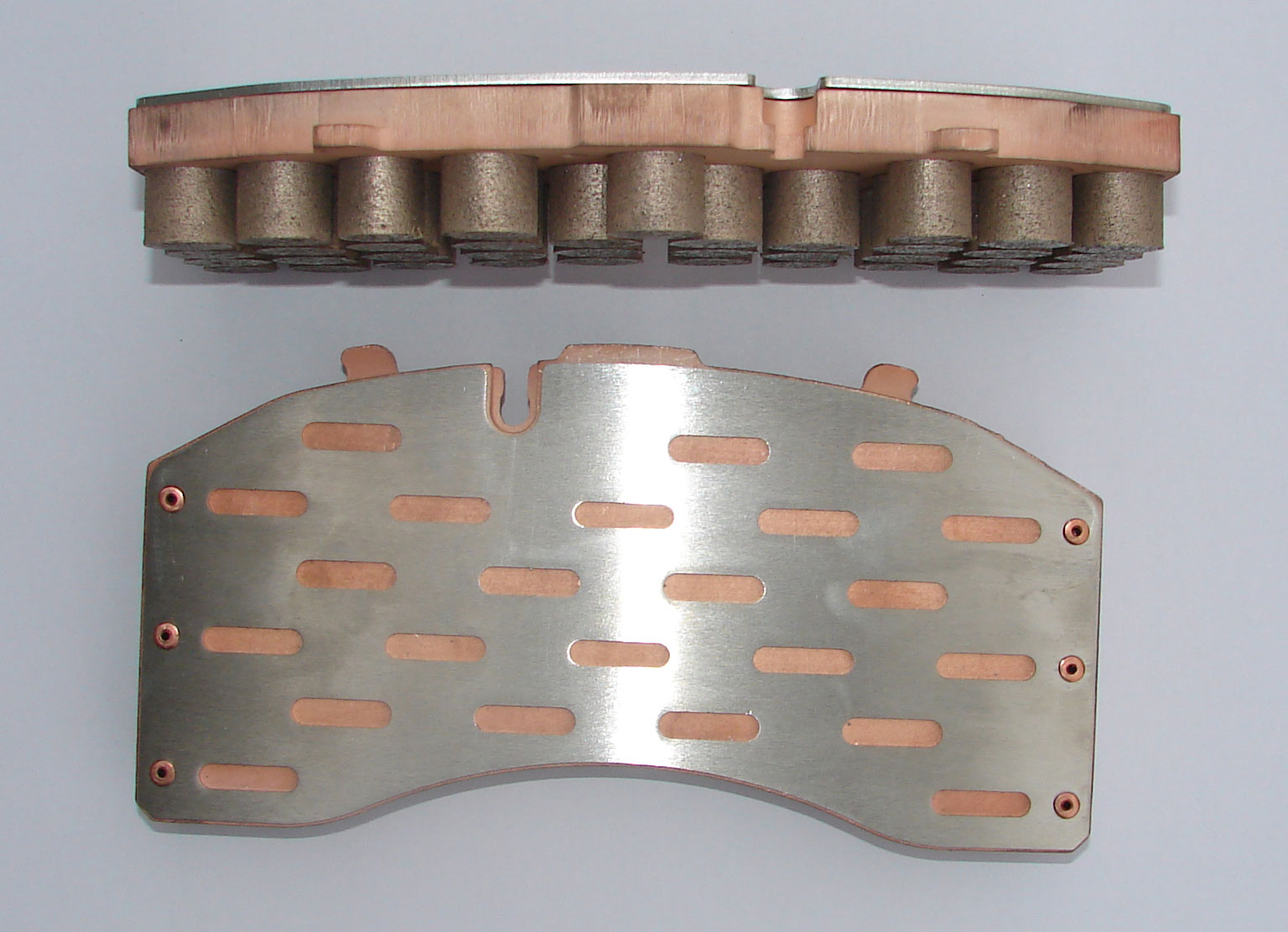

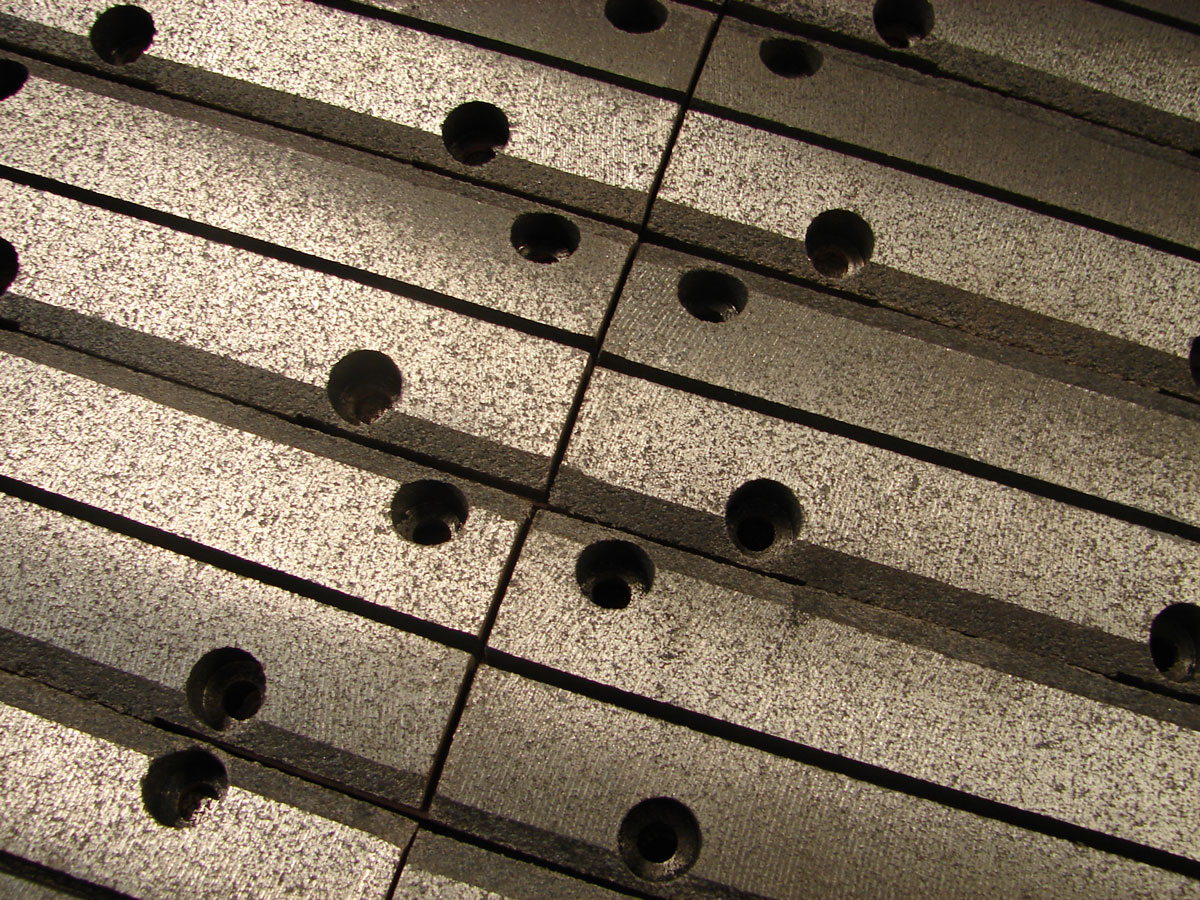

Sinter brake pads for cars

Characteristics and brakes function´s description:

Brakes use kinetic energy from weight and speed of the vehicle. This energy is tranferred on the rotating wheels. Brakes slow this wheels rotation and transform energy into pressure of brake mechanism and wheel suspension. Wheels are slowed with friction of brake shoes that are pushed agaist the braking surface. Brake shoes are handled with pedal or hand lever (parking brake of the rear axle).

There are mainly disc brake pads at the front. They consist of brake disc fitted on the axle and brake caliper seizing the brake disc. Brake disc is made of steel and brake lining is of sintered material. Brake shoes are pushed agaist brake disc by means of brake caliper. Brake fluid circulating in the brake lines transfers pressure from the pedal to the pistons of brake caliper that forces brake pads against brake disc.

There are mainly brake shoes at the rear. Brake shoes are located inside the brake drums. Brake lining is riveted on the steel shoes.

Master cylinder that is controlled with pedal has a separate operating space for brakes on the front and rear axle. This layout is called dual circuit brake system. The braking power is transferred via brake fluid circulating in the brake lines and pipes.

To read detailed descriptions of both compounds, please click on the pictures below.

How to install new car brake pads:

- Verify right selection of the brake pads at the dealer’s in accordance with the bike type and model year of your bike.

- Replace the brake pads as soon as the braking surface thickness has dropped below 2 mm.

- Protect brake pad surfaces from grease, oil and other chemical substances.

- Clean and degrease the brake wheels prior to installation of new brake pads.

- Replace damaged brake discs that reduce the braking effect and, at the same time, shorten the lifetime of the brake pads.

- Install the brake pads facing their braking surfaces towards the brake disc. Having completed the installation, check correct brake pads assembling and securing.

- Leave the installation of brake pads on a specialized servicing shop if lacking experience.

New Brake Pads Conditioning:

It is important to condition new linings after installation to obtain maximum service life and performance. If possible, do not install new brake discs while brake pads conditioning.

Brake rotors should be in the best condition possible. If different brake pads material was previously used, clean brake surface with sandpaper. If you feel that brake disc might be flawed (warped, demolished, the braking area is too worn etc.), you will have to mount new brake disc before brake pads conditioning otherwise you would risk low brake performance.

Make sure that brake pads are not too seized in the brake caliper. Check pistons properly, make sure that they are not stuck and that there is no rust.

Apply slow braking under low speed to create contact area between brake rotor and brake pads. This contact area should have 80-90% extention. DO NOT overload your brakes during conditioning! after several brakings under higher speed allow brakes to cool. Then you can use your brakes normally.